On 16 November 2013, a fire broke out in an industrial warehouse of NOVAUTO Spa in Cagliari, damaging the central room on the ground floor and part of the structural system, which consists of a pre-stressed reinforced concrete frame.

Built in 2010, the building is on two levels above ground and has a rectangular floor plan covering an area of 60 x 40 m. Prefabricated pre-stressed reinforced concrete slabs form the horizons and are bonded to the beams by a completion casting. The external walls are composed of the serial repetition of modular prefabricated panels, which on the ground floor are connected directly to the foundation curbs and lintels of the large openings. In contrast, the ties connecting them to the edge beams on the upper floor prevent transversal movement at the floor level but allow longitudinal sliding.

The ground floor has an intermediate height of 6 m. It is divided into three equal areas by walls transversal to the main façade, consisting of a layer of plaster, a brick face and thermal insulation, which, having a fire protection class of REI 120, limited the spread of fire to the central block. Conversely, the upper floor has an inter-floor height of 3.50 m and is configured as an ample open space.

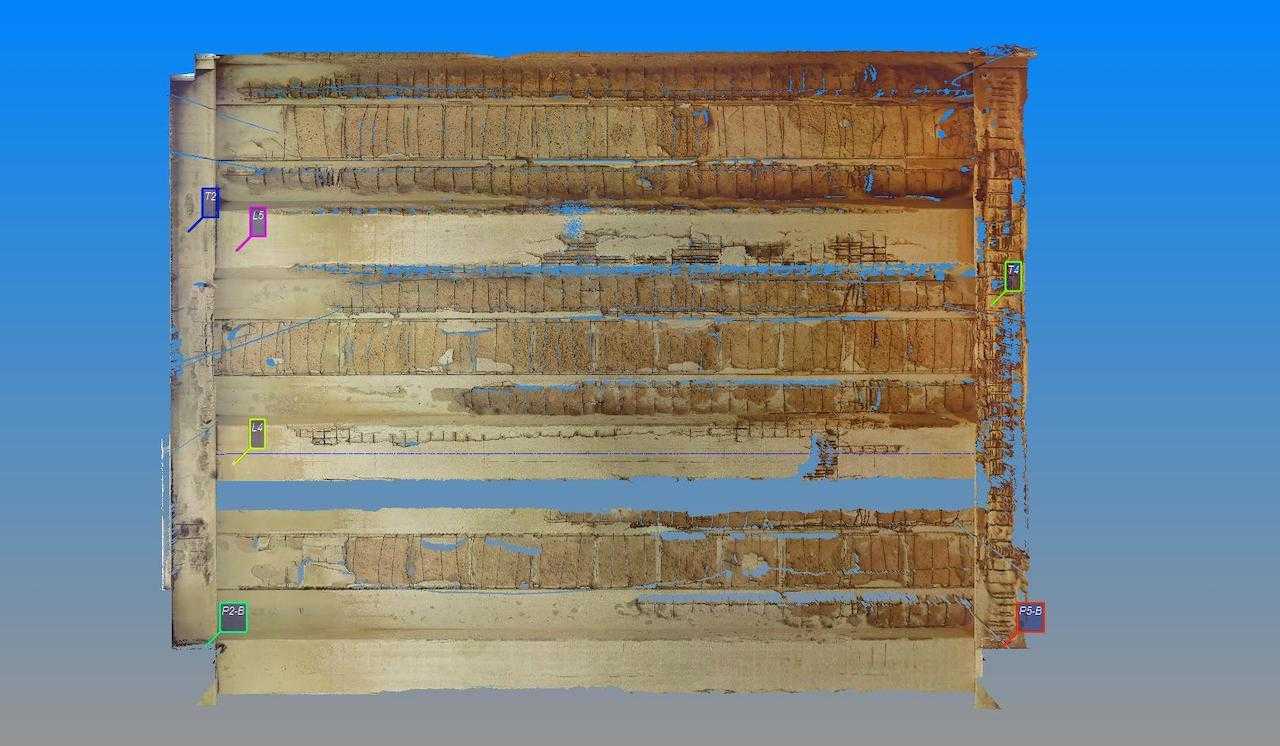

Secured Solutions conducted diagnostic investigations to define the most appropriate static rehabilitation measures. After an accurate inspection and study of the original project, to assess the integrity of the intermediate floor and thus be able to operate safely, a load test was carried out on a longitudinal beam using a tank progressively filled with water. It was thus possible to demonstrate that the action of the fire had not compromised the elastic behaviour of the structure. The next step coincided with the preparation of the geometric survey with a 3D Laser Scanner and the subsequent development of a three-dimensional model of the building, from which it emerged that the fire had not significantly altered the static pattern of the structural elements.

Based on a 1×1 m mesh, the SonReb (SONic + REBound) test was carried out on the precast concrete slab collaborating with the beams. This is one of the most effective non-destructive tests, which allows, by measuring the speed of propagation of the ultrasonic waves, to estimate the mechanical characteristics of the material and the presence of any alterations caused by the fire, such as micro-cracks, air bubbles, discontinuities, etc.

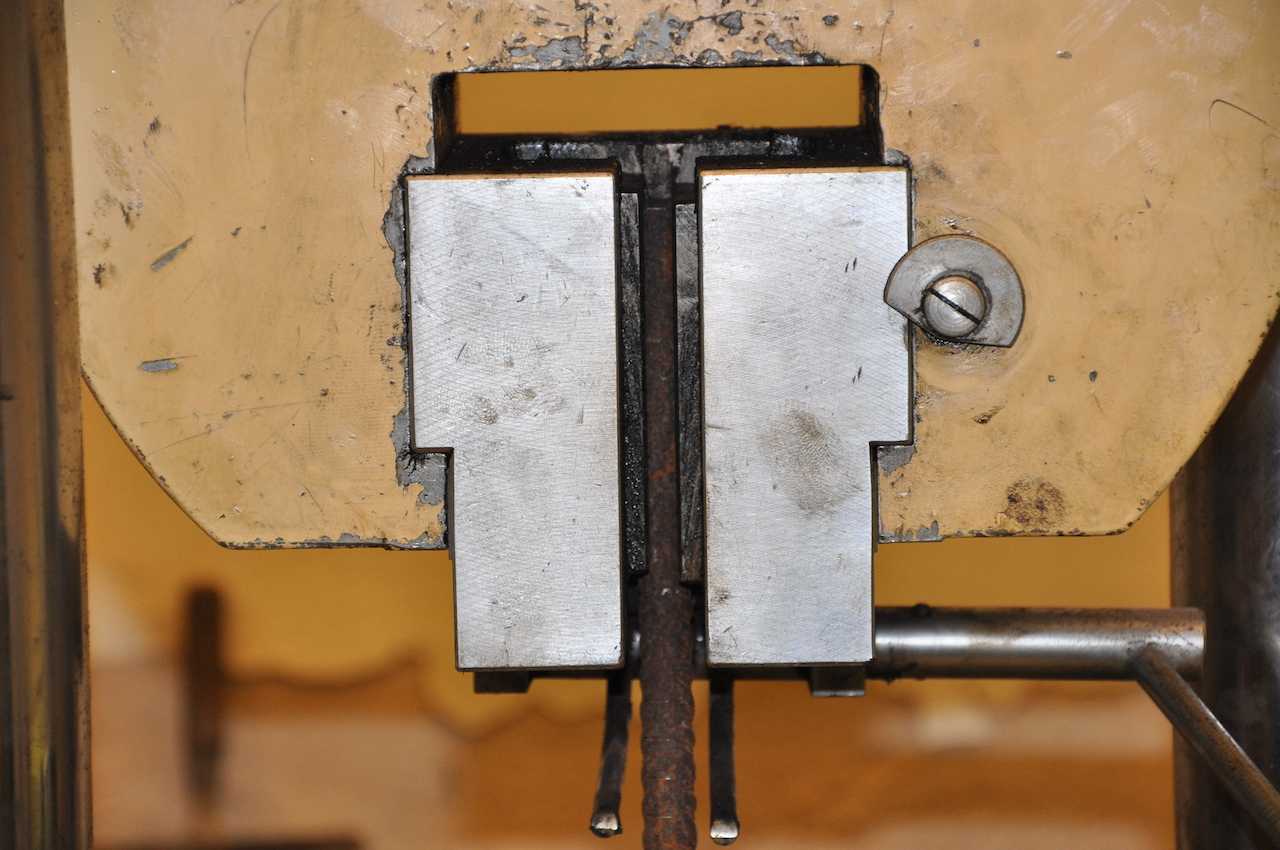

In addition, several cylindrical samples were extracted from columns and slabs in various parts of the building (coring), on which the destructive compressive strength test and the carbonation test were then performed, which consists of a colourimetric test, performed by spraying a 1% aqueous solution of phenolphthalein in ethyl alcohol on the surface of the concrete. The results showed no carbonation layer was present in all the elements analysed (floors, columns and beams). Instead, for the mechanical characterisation of the reinforcement bars, samples were taken from two pillars subjected to fire and from the ribbed slabs of the floor slab.

Finally, evaluating the residual load-bearing capacity of the structure as a whole required preparing the thermal zoning of the structural elements using state-of-the-art techniques, such as X-ray Diffraction (XRD), Thermogravimetric Analysis—differential Thermal Analysis (TG-DTA), Optical Microscopy (OM), and Scanning Electron Microscopy (SEM).

The investigations finally showed that the geometric alterations caused by the fire were not significant for static purposes. Therefore, the static restoration work involved restoring the original sections of the structural elements using compatible materials. In particular, for the pillars, this entailed removing the deteriorated concrete, inserting new reinforcement, and applying a repair mortar; for the beams, applying a steel fabric and a reconstruction mortar on the surface freed from the deteriorated concrete.