At the request of Sideralloys, Secured Solutions conducted the structural analysis of the Electrolysis Buildings, which are part of the large industrial complex in Portovesme. The objective was to verify the dimensional adequacy and strength of the vertical support elements and their foundations in anticipation of replacing overhead cranes with new lifting equipment.

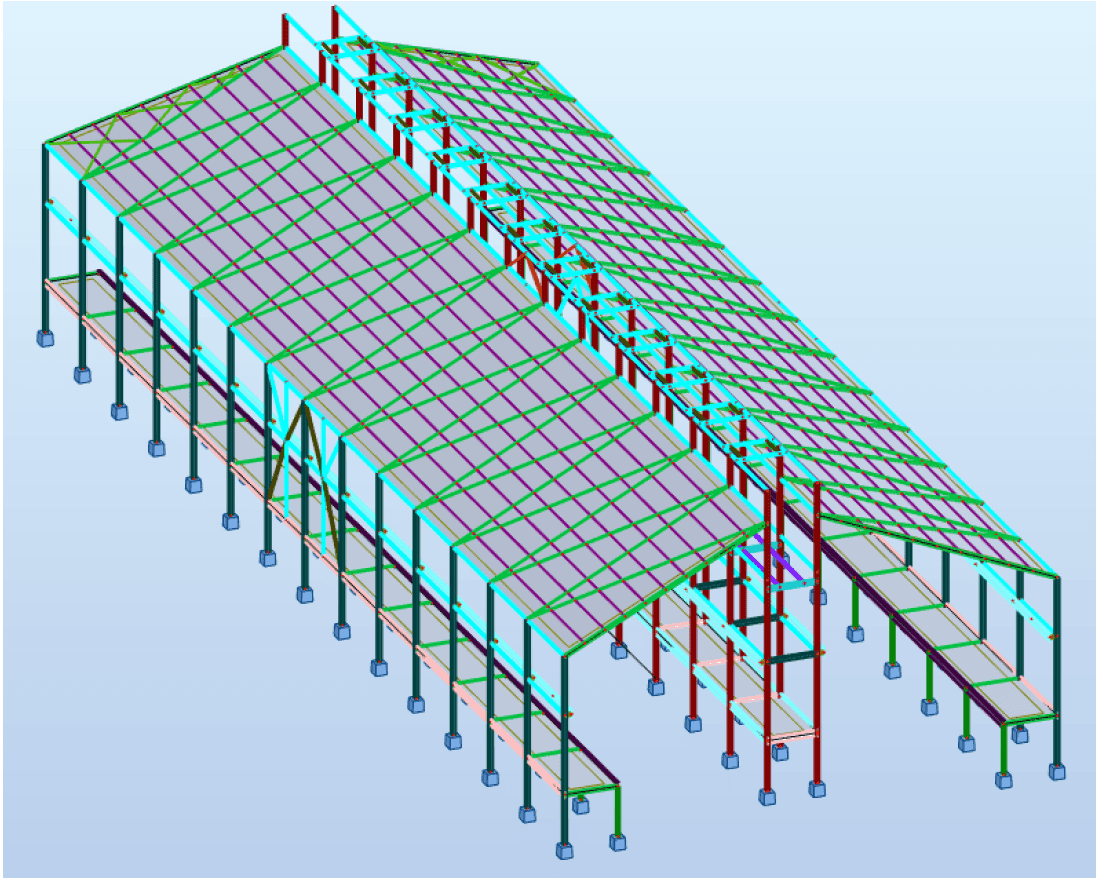

The Electrolysis Buildings, designed in 1970 by Società Anonima Elettrificazione (SAE), are two twin buildings divided by a 20 m wide longitudinal corridor between the Foundry Building and the Conversion Building. Each consists of three blocks, 201.60 m long and 38.60 m wide, enclosing a space composed of a 3.90 m central aisle and two 17.35 m side aisles dedicated to the crane’s operation.

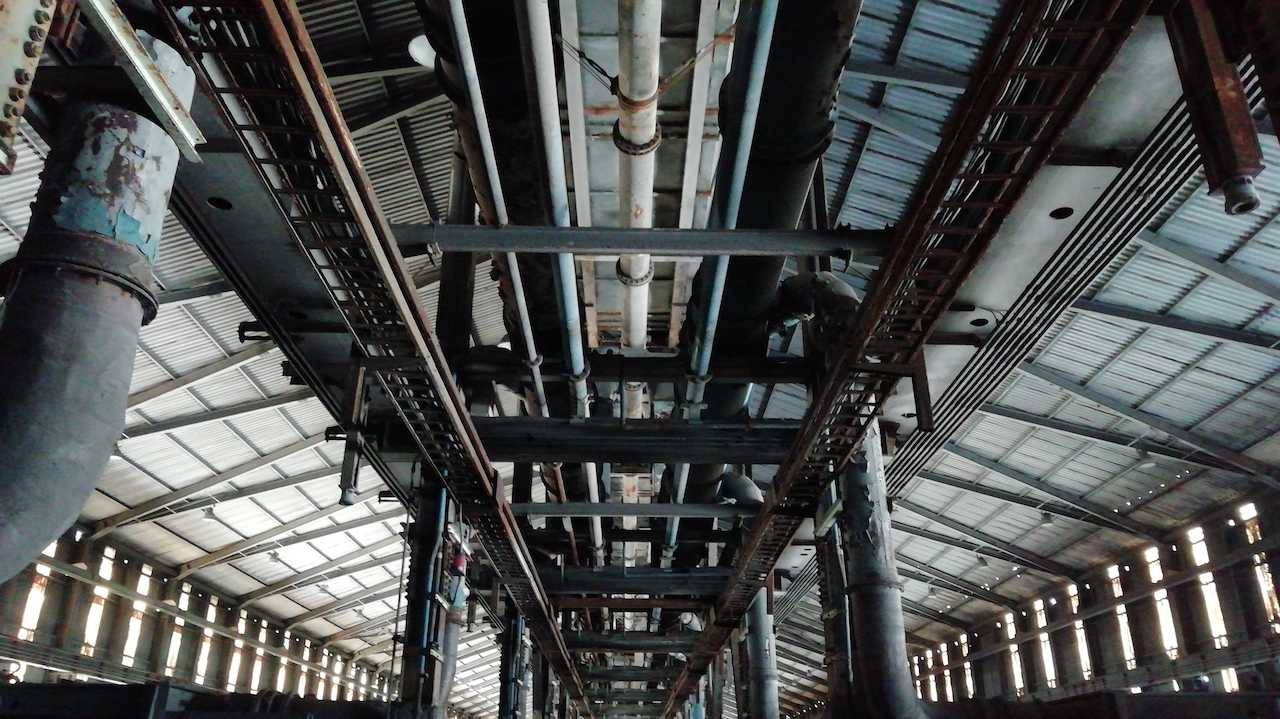

It is, therefore, an industrial building supported by an imposing and suggestive steel structure, formed by two rows of columns distributed with a 7.20 m centre-to-centre distance along the longitudinal perimeter fronts and by two internal rows, which draw the central aisle, using the same centre-to-centre distance but with a half-length offset. This is a construction choice that, on the three-dimensional plane, has produced an unprecedented multiple-frame scheme formed by lintels converging alternately inwards and outwards.

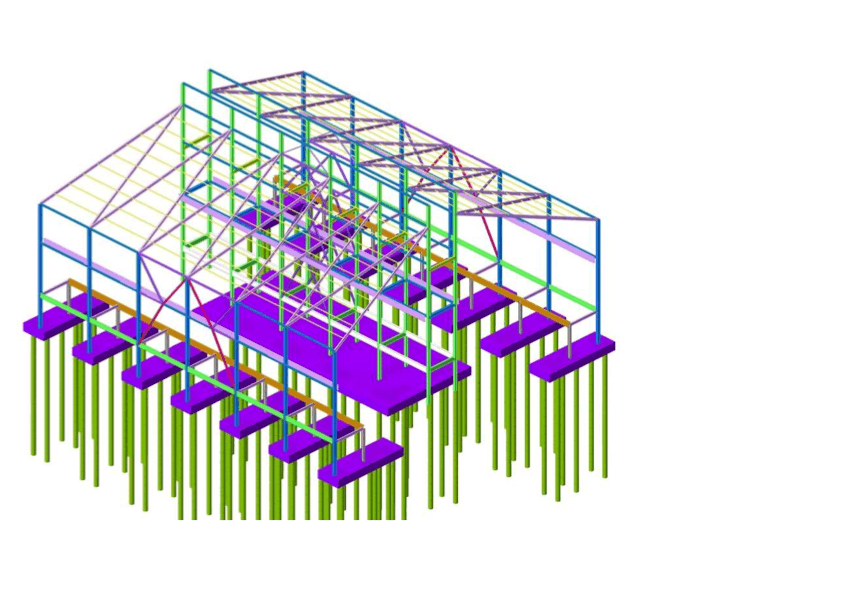

Along the side alignments and the central aisle, at a height of 4.25 m above ground level, are the reinforced concrete decks on which the machinery rests. The footing of the vertical supports is anchored through anchor bolts embedded in the reinforced concrete foundation, which consists of a slab and Franki-type driven piles. The central aisle is closed at the top by a shed roof, which houses the ventilators and is connected to the pitches of the side aisles, formed by a double frame of beams and a self-supporting shaped aluminium sheet. This material is also used in the cladding of the vertical walls, together with sheets of translucent material, which have the same shaping as the opaque ones, although dedicated to the passage of natural light. The external cladding is thus configured as a single skin, which, despite the complexity of the interior space, simply envelops the entire structure.

In full respect of the original configuration, based on information taken from archive material and assuming the heaviest load conditions, the analyses and verifications of the structure were carried out. Autodesk ROBOT Structural Analysis Professional software was used for the steelwork elements. At the same time, for the behaviour of the foundations, the choice fell on Aztec Informatica’s API Full software: both are based on finite element numerical models. The results of the calculations were confirmed by traditional calculation methods typical of building science and technology. In addition, based on considerations regarding tension and deformation states, the validity of the choices made in the schematisation and modelling of the structure and actions was assessed.

Based on the results obtained, structural reinforcement works were then designed to allow the replacement of the existing gantries with new-generation ones.